Services

From concept to mass production, all in one place

Changrun Plastic Co., Ltd. has been dedicated to plastic injection molding and integrated product development since its founding in 1978, boasting over 40 years of extensive experience and comprehensive equipment. We are not only an injection molding manufacturer but also an integrated contract manufacturing partner with capabilities in design, R&D, manufacturing, and post-processing. We assist clients in rapidly transforming concepts into high-quality products and achieving stable mass production.

Whether it's end-to-end ODM development or high-precision OEM injection manufacturing, we deliver flexible, reliable custom solutions for diverse industries.

Services

Business Operations

『ODM Projects』 One-Stop Full-Process Solutions

- Industrial Design (ID):Innovative Design and Ergonomic Optimization

- Mechanical Engineering (ME):Structural Manufacturability Assessment and Strength Analysis

- Mockup Rapid Validation:3D prototyping and functional testing to ensure design feasibility

- Plastic molds:Optimized flow channels and CNC machining—we integrate professional expertise across every development stage to shorten development cycles, enhance mass production quality, and help you seize market opportunities faster!

『ODM Projects』 One-Stop Full-Process Solutions

From concept to mass production, we provide:

- Industrial Design (ID):Innovative Design and Ergonomic Optimization

- Mechanical Engineering (ME):Structural Manufacturability Assessment and Strength Analysis

- Mockup Rapid Validation:3D prototyping and functional testing to ensure design feasibility

- Plastic molds:Optimized flow channels and CNC machining—we integrate professional expertise across every development stage to shorten development cycles, enhance mass production quality, and help you seize market opportunities faster!

『OEM Projects』Comprehensive Precision Engineering Plastic Injection Molding Services

- 3C Product Housings: Lightweight, impact-resistant, with enhanced texture and appearance

- LED/Optoelectronic Components: High-temperature and UV resistant, ensuring long-term stability

- Semiconductor Test Fixtures: High-precision positioning with excellent chemical resistance

- Medical Device Housings: Antibacterial-grade materials compliant with international regulations

- Electronic Product Casings: EMI/RFI shielding for interference protection

- Industrial Machinery Parts: Wear-resistant and corrosion-resistant, built for harsh environments

『OEM Projects』Comprehensive Precision Engineering Plastic Injection Molding Services

By combining high-performance engineering plastics with advanced injection molding technology, we create high-quality components tailored to functional and specialized structural requirements. Key application areas include:

- 3C Product Housings: Lightweight, impact-resistant, with enhanced texture and appearance

- LED/Optoelectronic Components: High-temperature and UV resistant, ensuring long-term stability

- Semiconductor Test Fixtures: High-precision positioning with excellent chemical resistance

- Medical Device Housings: Antibacterial-grade materials compliant with international regulations

- Electronic Product Casings: EMI/RFI shielding for interference protection

- Industrial Machinery Parts: Wear-resistant and corrosion-resistant, built for harsh environments

『Post-Processing Services』One-Stop Precision Handling

- Coating/Painting: UV curing, metallic finish

- Printing: UV, screen, digital

- Ultrasonic Welding: Seamless, high-strength bonding

- Assembly & Testing: Screws, snap-fits, functional inspection

- Custom Packaging: Insert design, shipment inspection

『Post-Processing Services』One-Stop Precision Handling

- Coating/Painting: UV curing, metallic finish

- Printing: UV, screen, digital

- Ultrasonic Welding: Seamless, high-strength bonding

- Assembly & Testing: Screws, snap-fits, functional inspection

- Custom Packaging: Insert design, shipment inspection

Services

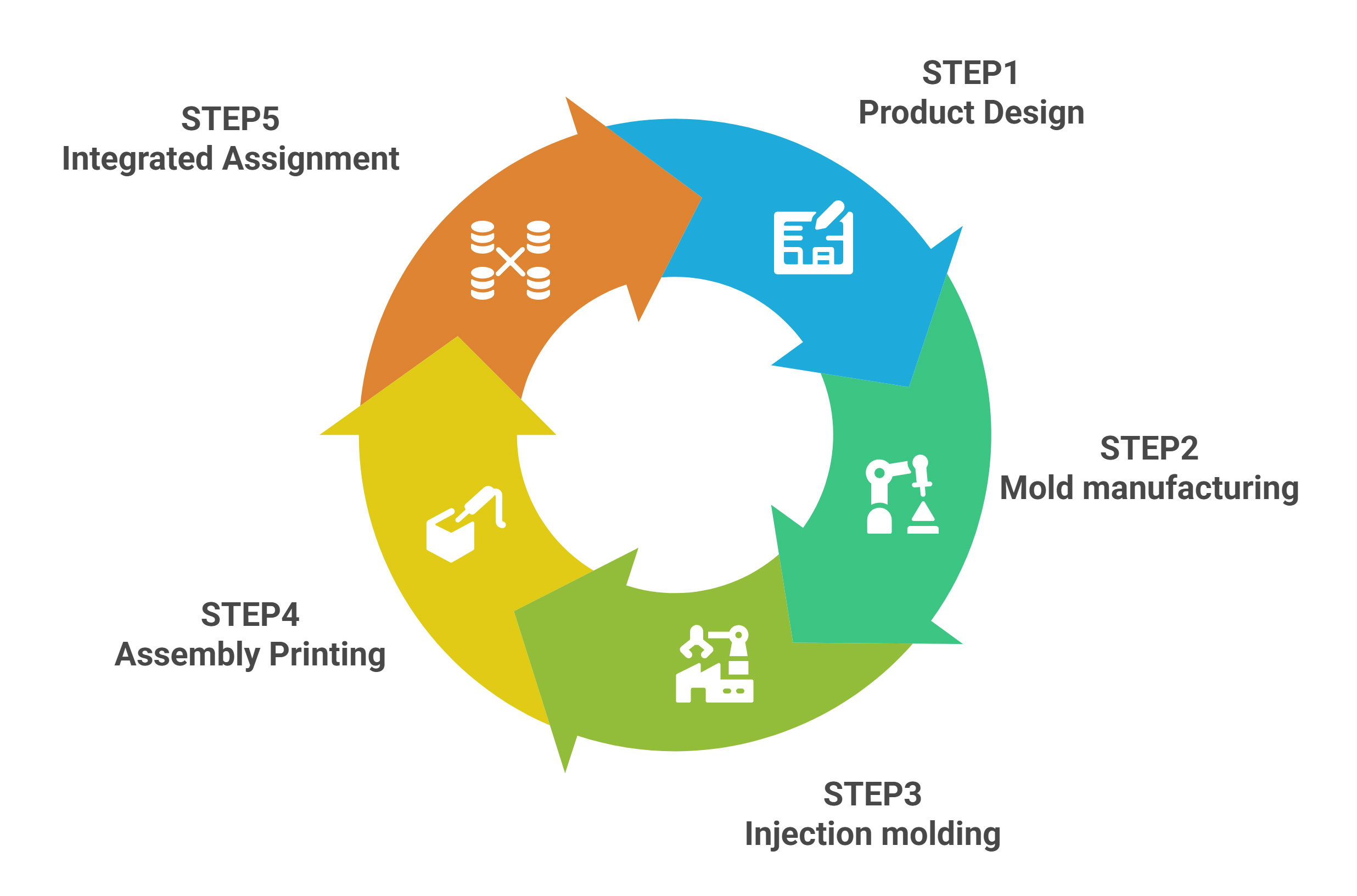

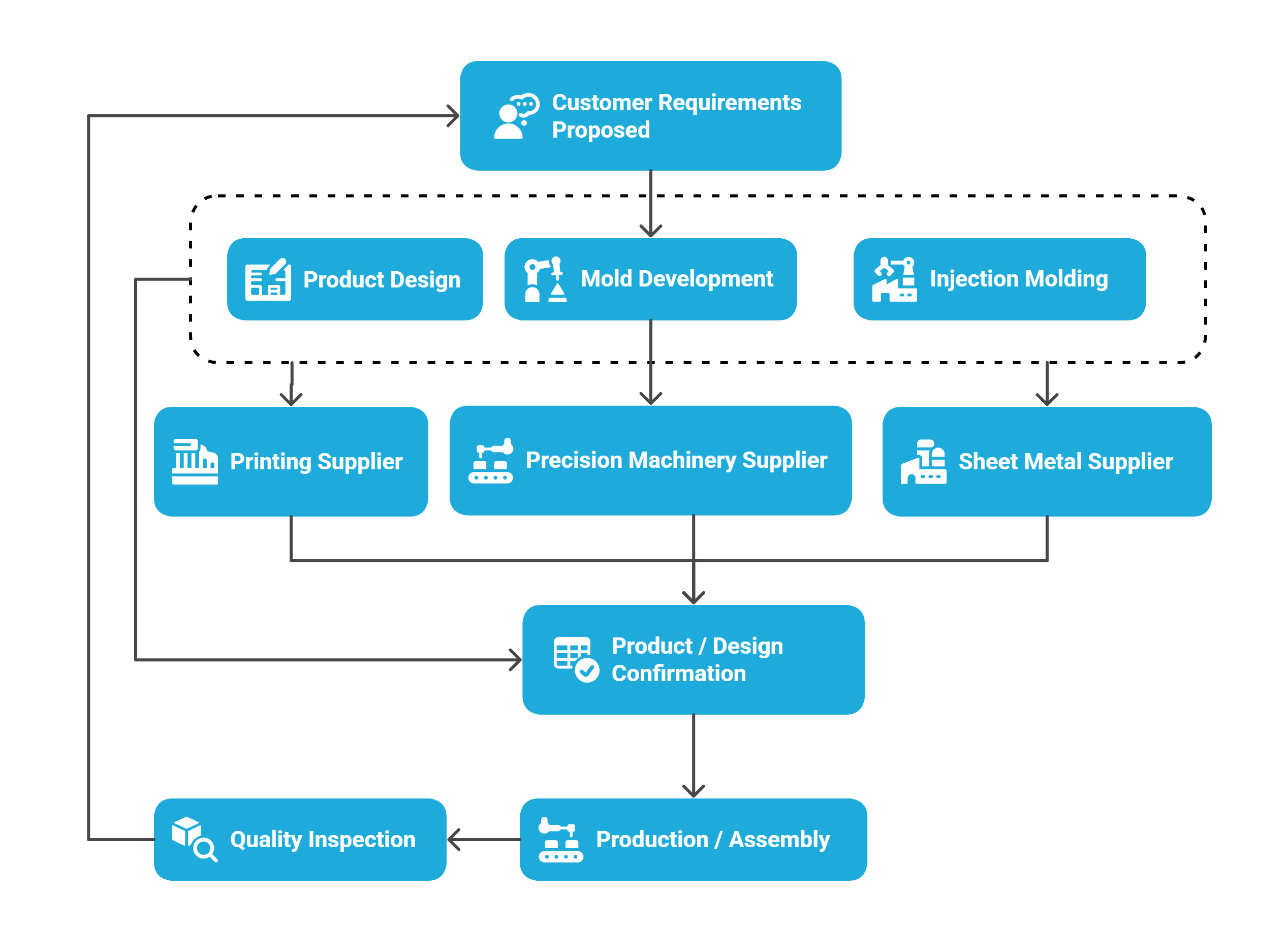

Contract Manufacturing Process

Whether you require product design and development support or seek a reliable injection molding partner, Changrun Plastics will collaborate with you to create competitive plastic products, grounded in professionalism, efficiency, and quality.

Contact us today to explore your new integrated manufacturing solution!

Why Choose Us?

Why choose Changrun Plastics?

Price Advantage × Integrated Services

Full-cycle oversight of project feasibility

We incorporate process evaluation and cost analysis from the design phase to identify high-cost or unfeasible manufacturing risks early on. This helps clients grasp the true feasibility of their projects and avoid the pitfall of designs that look good but cannot be mass-produced.

High-Efficiency Schedule Management

Seamless integration of product development, mold manufacturing, and mass production processes reduces cross-departmental coordination time. Professional integration minimizes communication costs between design and manufacturing teams, ensuring critical timelines are met and business opportunities are not missed.