Introduction

Equipment Introduction

Injection molding machine – Total of 6 units

- TMC 60T 1 unit

- TMC 90T 1 unit

- TMC 150T 3 unit

- TMC 250T 1 unit

Introduction

Equipment Introduction

- Mold Temperature Controllers (±1°C tolerance) – 3 units

- Ultrasonic Machines (15KHz / 20KHz) – 3 units

- Bucket-Type Hot Air Circulation Dryers – 6 units

- Dehumidifying Dryer – 1 unit

- Vacuum Automatic Filling Machine – 6 units

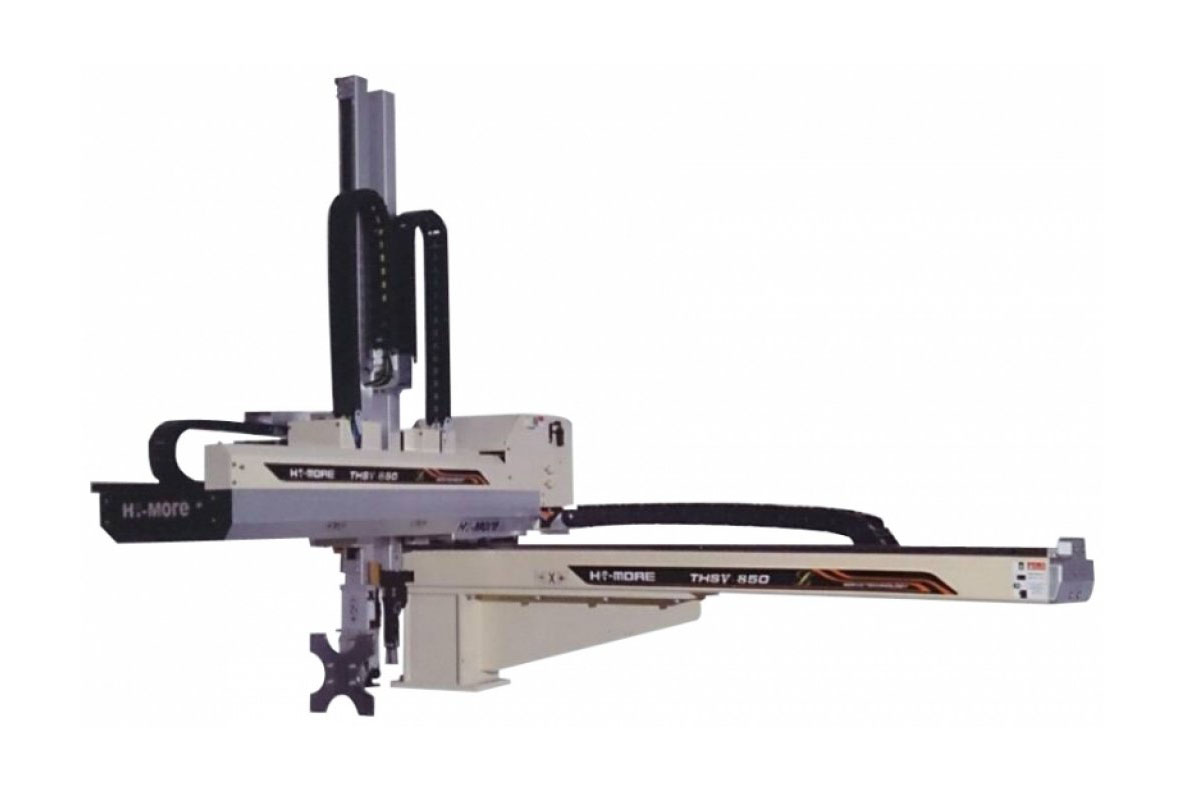

- Horizontal 5-Axis Servo

- Robotic Arm – 4 units Pneumatic Cantilever

- Robotic Arm – 2 units

- Random Grinder – 4 units

- Sprue Scrap Grinder – 4 units

- Mold Storage Rack – 5 sets

- Electric Pallet Jack – 1 unit

Introduction

Equipment Introduction

- Non-contact Infrared Mold Thermometer — Precisely monitors mold forming temperatures to ensure process stability

- Precision Vernier Caliper — Delivers high-accuracy dimensional measurements to guarantee product dimensional accuracy

High-efficiency - Electronic Weighing Machine — Accurately controls finished product weight to meet quality standards

- Thickness Gauge — Inspects product wall thickness consistency to enhance structural reliability

- Standard Thread Gauges — Verify thread specifications for assembly quality assurance

- Height Gauges — Strictly control verticality and height tolerances to ensure product consistency

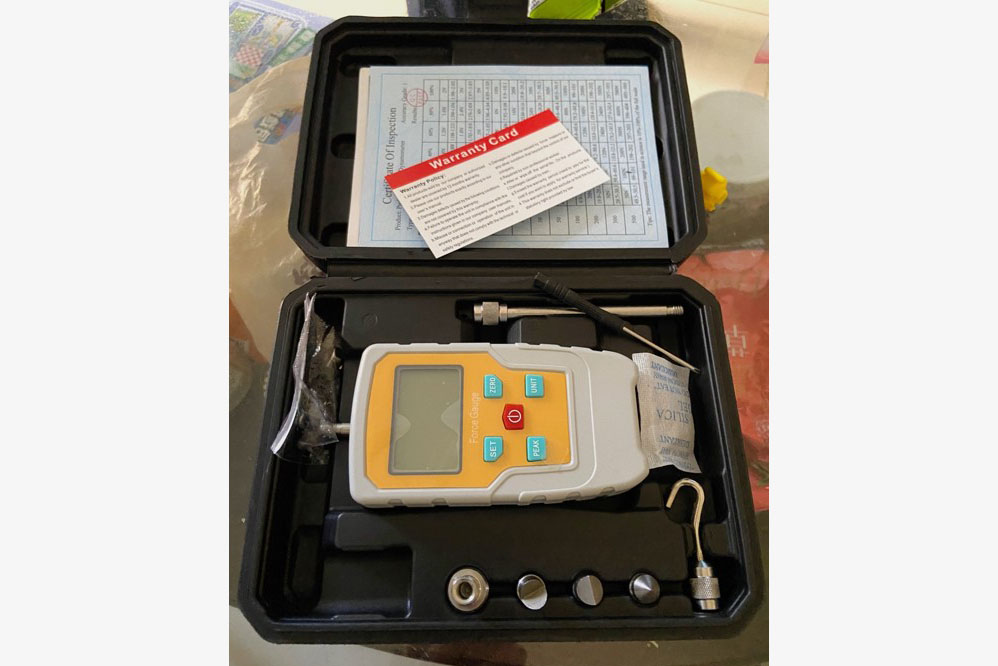

- Digital Surface Resistivity Tester

- RT-1000 — Tests product surface conductivity for electronic and anti-static applications