Quality Assurance

Over 40 Years of Practical Experience × End-to-End Process Control

We understand that quality is the lifeline of an enterprise. At CHARNG RUHN PLASTIC, we adhere to strict professionalism and rigor, inspecting every step from raw material receipt to finished product delivery to ensure that every product delivered meets high-quality standards.

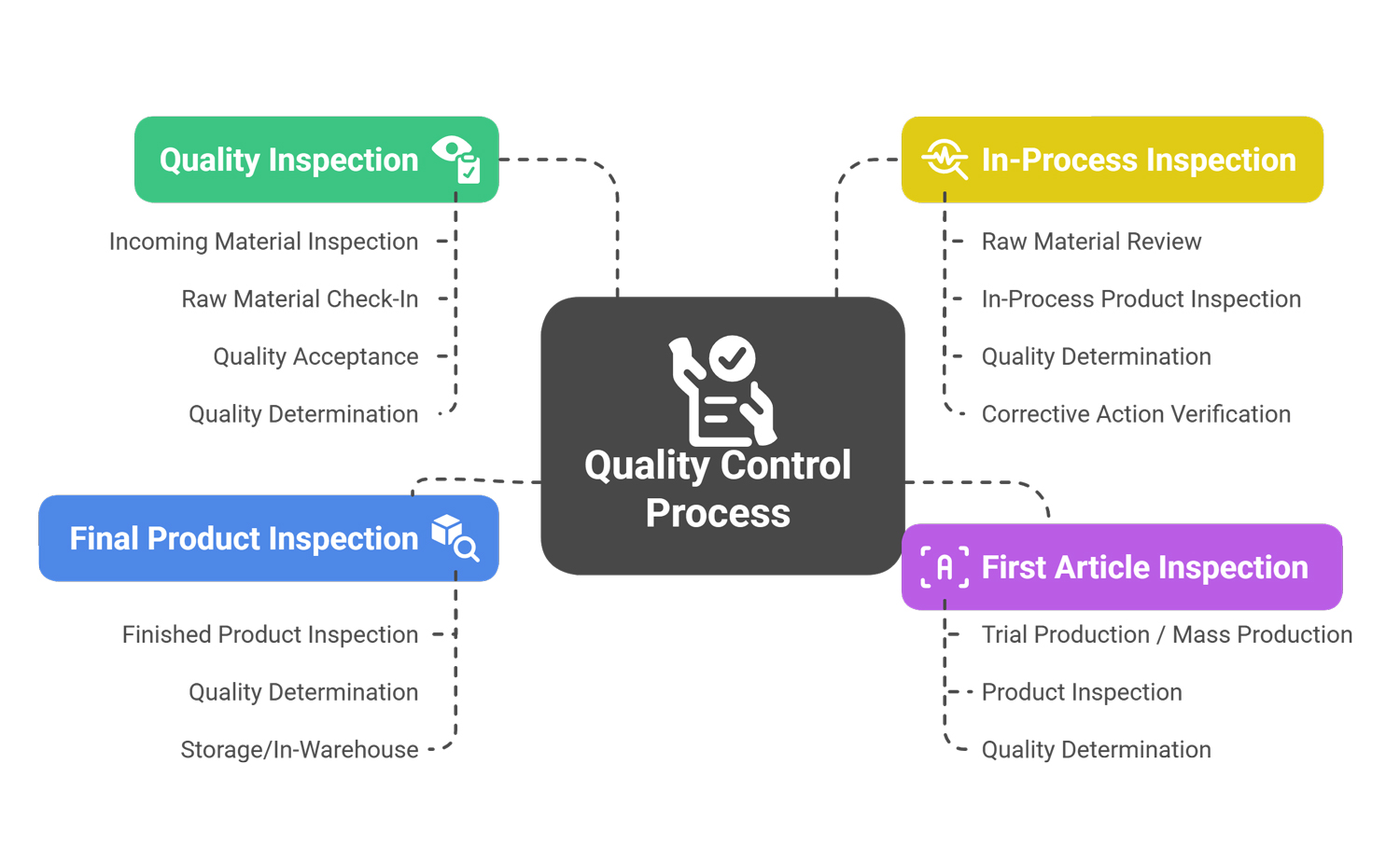

To guarantee product stability and reliability, we have established a comprehensive quality control process that covers four key stages from raw materials to finished products:

Services

ISO 9001 Certified × Standardized Quality Management

To ensure product quality and customer satisfaction, CHARNG RUHN PLASTIC has implemented and obtained ISO 9001 international quality management system certification. This establishes a scientific, standardized, and sustainable quality control process aimed at achieving traceable quality, manageable risks, and preventive measures.

Continuous Improvement (PDCA Management Cycle)

By implementing the “Plan → Do → Check → Act” cycle, every inspection and feedback becomes a driving force for continuous quality improvement.

Supplier Quality Control

A supplier evaluation system is established to regularly review the quality of raw materials and subcontractors, ensuring quality control from the very source.

Internal Audit System

Regular internal quality audits and employee training are conducted to ensure effective implementation of the system and continuous improvement in line with current standards.

Why Choose Us?

Why choose Changrun Plastics?

Price Advantage × Integrated Services

Full-cycle oversight of project feasibility

We incorporate process evaluation and cost analysis from the design phase to identify high-cost or unfeasible manufacturing risks early on. This helps clients grasp the true feasibility of their projects and avoid the pitfall of designs that look good but cannot be mass-produced.

High-Efficiency Schedule Management

Seamless integration of product development, mold manufacturing, and mass production processes reduces cross-departmental coordination time. Professional integration minimizes communication costs between design and manufacturing teams, ensuring critical timelines are met and business opportunities are not missed.